偏航/转子系列Yaw/Rotor Brake Pads

1.三鸦 致力于提高 偏航摩擦片的摩擦系数 增大制动力

三鸦 is committed to improving the friction coefficient of yaw friction plates and increasing braking force

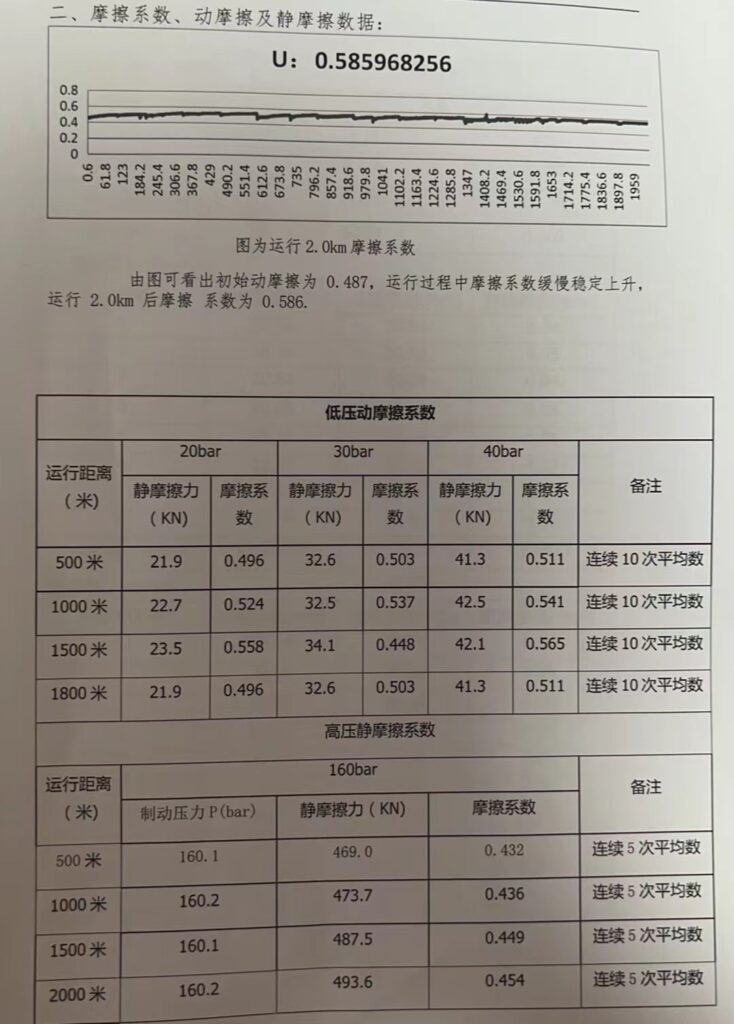

三鸦 深耕风电摩擦领域多年,随着大兆瓦数风机的面世与升级,对偏航制动力的要求越来越高。KUMABEAR研发了三鸦-F3牌号材料。这个材料通过双改性黏合树脂+半改性纤维素等方式,将摩擦系数提高到了0.58,能满足大部分高制动力要求风机及地区的要求。同时,提供三鸦-F3+的方案服务,根据地区环境的实际需要,微调摩擦系数。

三鸦 has been deeply involved in the field of wind power friction for many years. With the emergence and upgrading of large megawatt wind turbines, the requirements for yaw braking force are becoming increasingly high. 三鸦 has developed the KUMABEAR-F3 grade material. This material has increased the friction coefficient to 0.58 through double modified adhesive resin and semi modified cellulose, which can meet the requirements of most high braking force fans and regions. At the same time, we provide 三鸦-F3+solution services and fine tune the friction coefficient according to the actual needs of the regional environment.

三鸦-F3牌号与VULTURE-F3+材料经过实验及挂机,具有稳定的高摩擦系数

The 三鸦-F3 grade and VULTURE-F3+material have undergone experiments and hanging, and have stable high friction coefficients

2.三鸦 致力于降低 偏航摩擦片的磨损率 增加寿命

三鸦 is committed to reducing the wear rate of yaw friction plates and increasing their lifespan

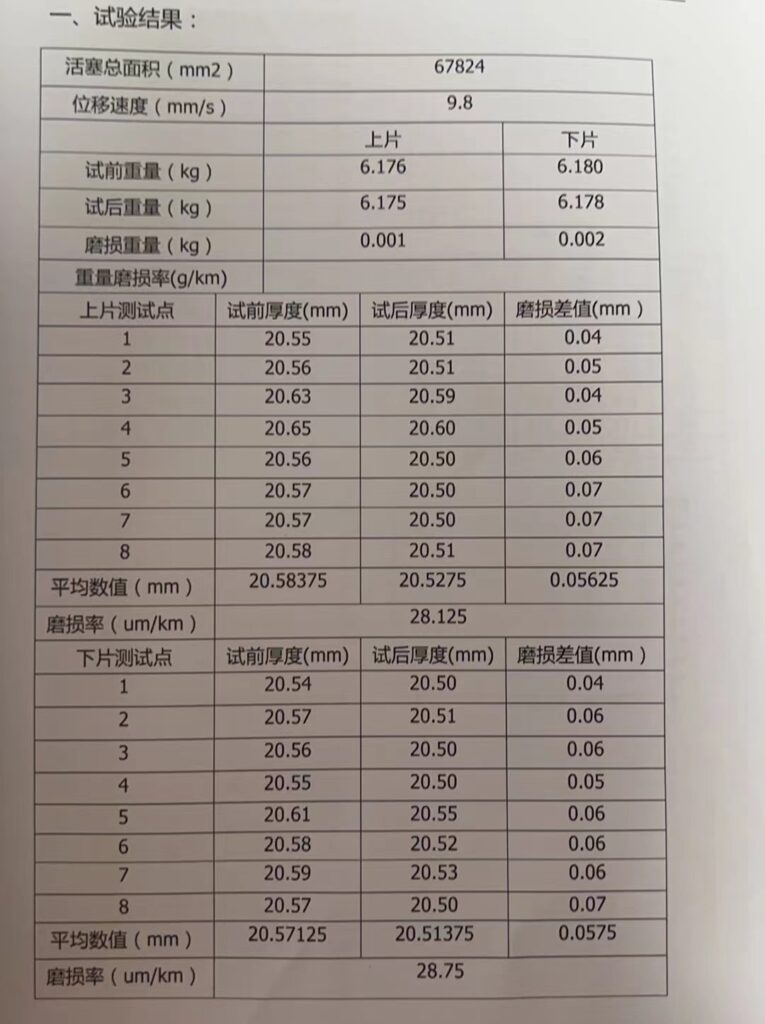

市面常用一型号偏航摩擦片磨损率为28.75(um/km),过快的消耗为业主客户带来了经济与人工的压力。VULTUR经过研发,提出了牌号VULTUR-F4的解决方案,极大的降低了磨损率,延长寿命。

The wear rate of a commonly used type of yaw friction plate in the market is 28.75 (um/km), and the rapid consumption has brought economic and labor pressure to the owners and customers. 三鸦 has developed a solution for the brand VULTUR-F4, which greatly reduces wear rates and extends lifespan.

三鸦-F4牌号将平均磨损率从 28um/km 降到了

5-14 um/km

The 三鸦-F4 grade has reduced the average wear rate from 28um/km to 5-14 um/km

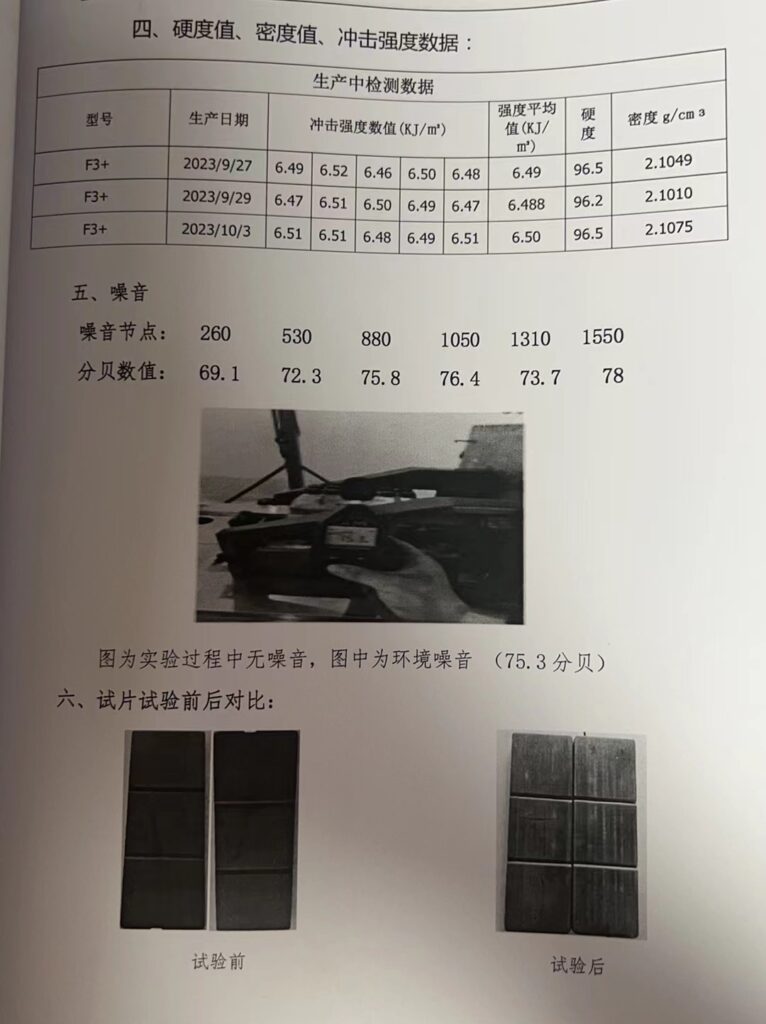

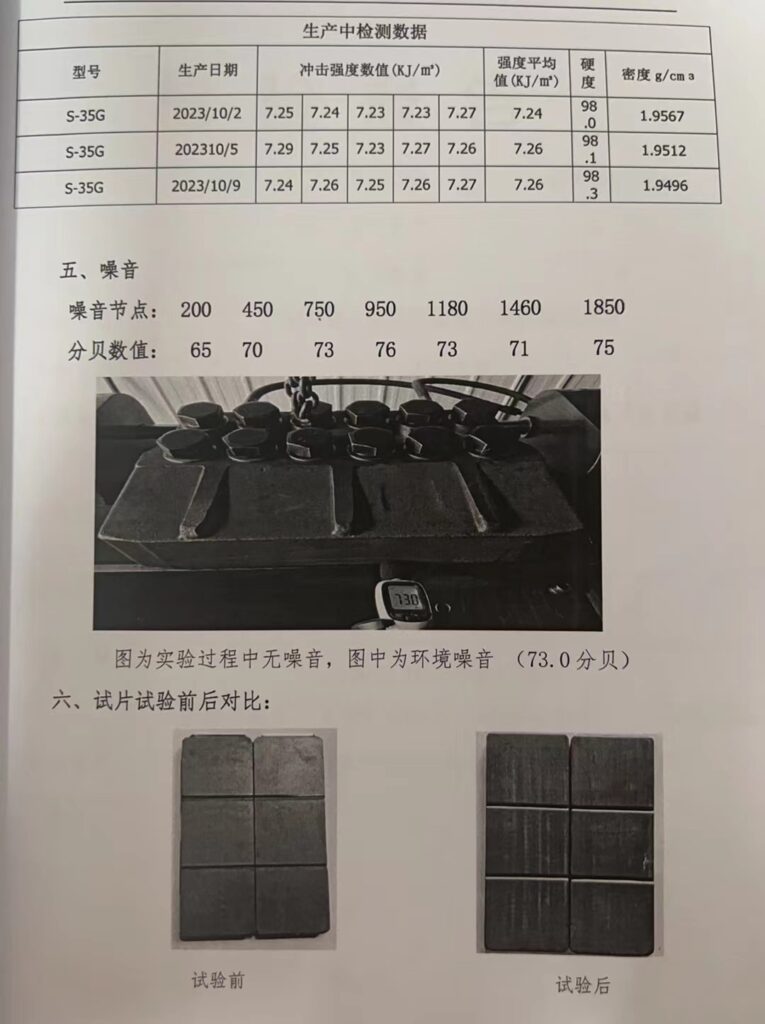

3. 三鸦致力于降低 偏航摩擦片的噪音

三鸦is committed to reducing the noise of yaw friction plates

偏航工作噪音的现象会严重影响生态环境,同时也会造成偏航制动衬垫伤盘,制动器损伤,塔筒振动报警停机等风机运行故障。这些故障严重影响运营效益与当地环境保护。针对如何规避或降低偏航制动时的噪音问题,三鸦从偏航衬垫(降噪材料)角度来提出解决方案。VULTURE通过研发自产的温敏感改性树脂及规律油膜层破坏的硬质材方式,提出了三鸦-F6降噪型偏航摩擦片材料。

The phenomenon of yawing work noise can seriously affect the ecological environment, and also cause damage to the yawing brake pad, brake, tower vibration alarm, shutdown and other wind turbine operation faults. These faults seriously affect operational efficiency and local environmental protection. 三鸦 proposes a solution from the perspective of yaw pads (noise reducing materials) to avoid or reduce noise during yaw braking.三鸦 has proposed the 三鸦E-F6 noise reducing yaw friction plate material through the development of self-produced temperature sensitive modified resins and hard materials with regular oil film layer damage.

三鸦-F6降噪型偏航摩擦片材料将风机偏航噪音平稳的控制在了85分贝以下

The 三鸦E-F6 noise reducing yaw friction plate material smoothly controls the yaw noise of the wind turbine below 85 decibels

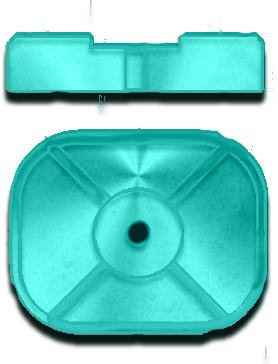

4. 三鸦 致力于提高 偏航电机电磁制动器摩擦片 高耐温、高耐磨、降尘

三鸦 is committed to improving the high temperature resistance, wear resistance, and dust reduction of the friction plates of the yaw motor electromagnetic brake

偏航电机电磁制动器在工作时经常出现高温高强等情况,这使得市面常规电磁抱闸摩擦片出现烧焦、断裂情况。不耐高温(可能持续)、强度低是抱闸片弊端

The electromagnetic brake of the yaw motor often experiences high temperature and high strength during operation, which leads to the burning and breaking of the friction plate of the conventional electromagnetic brake on the market. The disadvantages of brake pads are their inability to withstand high temperatures (which may persist) and low strength

三鸦的解决方案

三鸦-FDB系列具有高耐温性能

三鸦-BFK系列具有高耐磨性能

三鸦’s Solution VULTUREKUMABEAR’s Solution

The 三鸦-FDB series has high temperature resistance performance

The 三鸦-BFK series has high wear resistance

稳定的扭矩+高温温差变化耐性+变化受压强度抗性 是电磁抱闸片寿命延长的关键

Stable torque, resistance to changes in high temperature and temperature difference, and resistance to changes in compressive strength are the key factors for extending the service life of electromagnetic brake pads

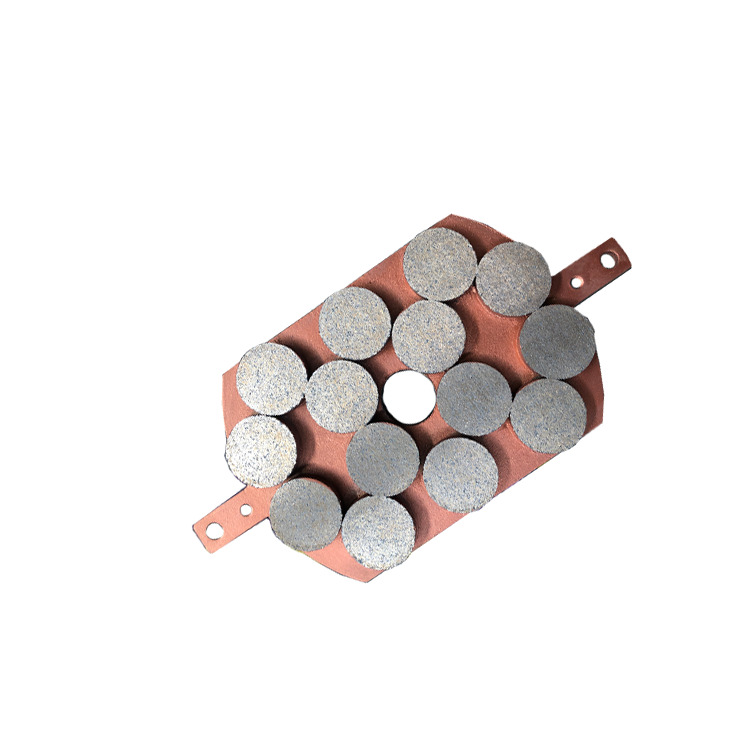

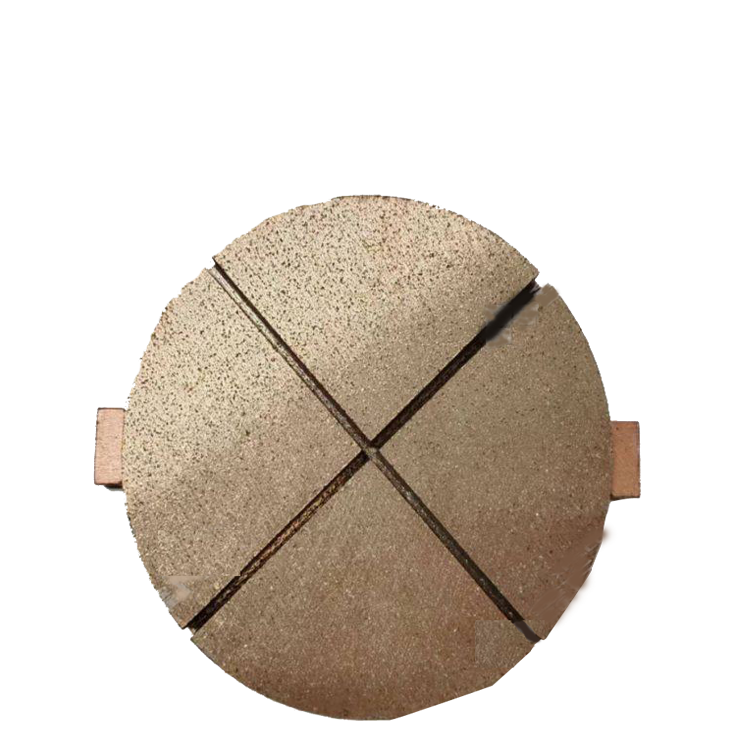

5.高速主轴烧结系列Sintered Brake Pads

高速主轴烧结系列Sintered Brake Pads 问题及解决方案

Problem and Solution of Sintered Brake Pads in High Speed Spindle Sintering Series

三鸦 致力于进一步提高 高速主轴风电机摩擦片 高耐磨特性

三鸦 is committed to further improving the high wear resistance of friction plates in high-speed spindle wind turbines

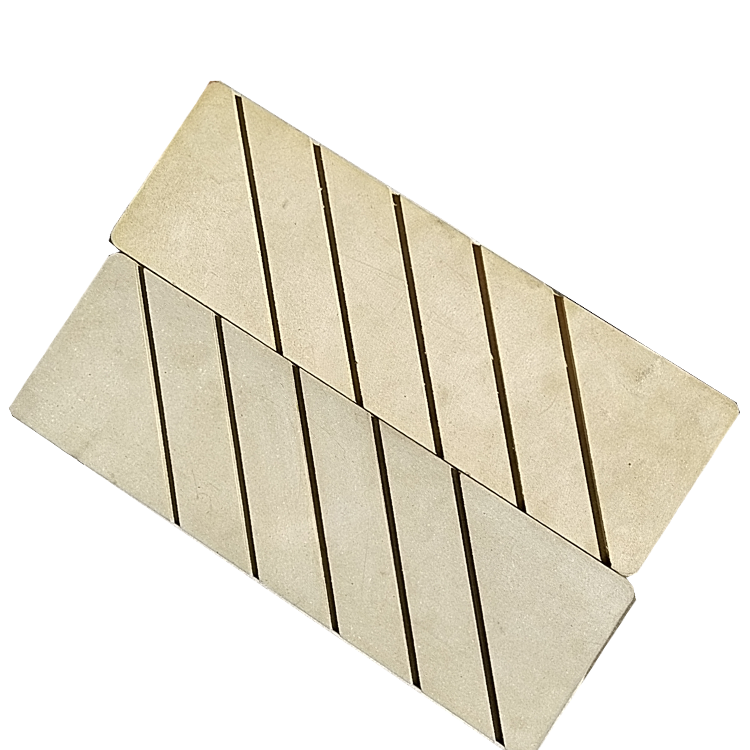

一般高速主轴摩擦片由 铜基粉末冶金烧结所制造,这一技术经过多年发展,已经相对成熟与稳定。

三鸦 在这一成熟稳定的基础上,进行了耐磨性改进的方案。

三鸦 通过点多合金的辅助+两段烧的模式方案,将主轴摩擦片的耐磨性进一步的提高。

Generally, high-speed spindle friction plates are manufactured by copper based powder metallurgy sintering, which has been relatively mature and stable after years of development.

三鸦 has implemented a wear resistance improvement plan based on this mature and stable foundation.

三鸦has further improved the wear resistance of the main spindle friction plate through the assistance of point multi alloy and two-stage burning mode scheme.

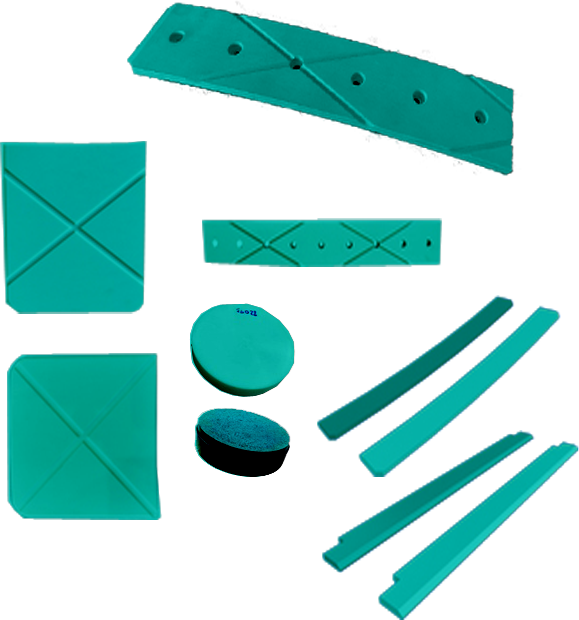

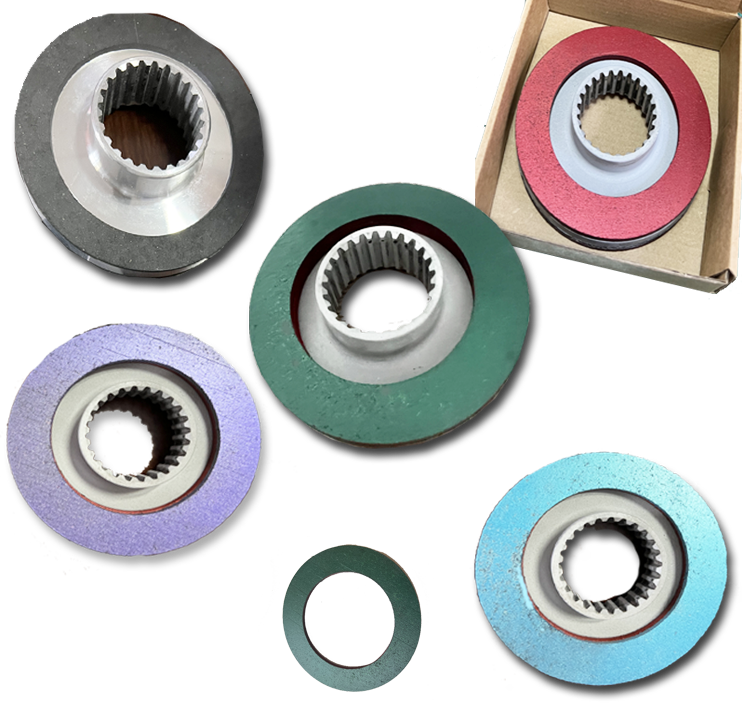

6.阻尼系列问题及解决方案 Slide Yaw Wear Pads Problem and Solution

阻尼系列问题及解决方案 Slide Yaw Wear Pads Problem and Solution

阻尼摩擦在风机运行中扮演者重要角色 ——三鸦 致力于阻尼摩擦片耐磨性问题解决方案

Slide Yaw Wear Pads plays an important role in the operation of wind turbines and 三鸦 is committed to providing solutions for the wear resistance of damping friction plates

“不耐磨”是风电阻尼摩擦片的通病 ,KUMABEAR的KUMABEAR-GHARED9010材质

‘Not wear-resistant’ is a common problem with wind power damping friction plates. 三鸦-GHARED9010 material from VULTURE

“不耐磨”是风电阻尼摩擦片的通病

‘Not wear-resistant’ is a common problem with wind power damping friction plates

VULTURE 的三鸦 -阻尼材质增大了摩擦材的韧性,降低磨损率

三鸦 ‘s 三鸦 damping material increases the toughness of the friction material and reduces the wear rate

三鸦的三鸦-GHARED9010材质采用新型配方,将双改性特陶与多合金分段融合在一起,将磨损率降到传统的1/5左右

VULTURE-GHARED9010 material from KUMABEAR adopts a new formula, which combines double modified special ceramics and multi alloy segments together, reducing the wear rate to about 1/5 of the traditional one